Supply chain optimization is a strategic approach that aims to maximize the efficiency and effectiveness of a company’s supply chain processes. It involves the careful analysis and improvement of various components, such as demand forecasting, inventory management, logistics, and supplier relationships.

Definition and Importance

Supply chain optimization refers to the systematic planning and execution of strategies to enhance the flow of goods, services, and information from the point of origin to the point of consumption. It focuses on eliminating bottlenecks, reducing costs, improving productivity, and delivering products or services to customers on time.

The importance of supply chain optimization cannot be overstated. In today’s dynamic business environment, companies face numerous challenges, including globalization, increased customer expectations, and rapidly evolving technologies. Supply chain optimization provides a framework to address these challenges effectively.

Overview of How Supply Chain Optimization Impacts Businesses

Businesses across diverse industries experience significant impacts as a result of supply chain optimization. Through the streamlining of processes and the optimization of resources, organizations can attain a multitude of valuable advantages:

Cost Savings

Supply chain optimization helps in identifying and eliminating inefficiencies, reducing inventory holding costs, minimizing transportation expenses, and optimizing production processes.

Enhanced Customer Satisfaction

A well-optimized supply chain enables faster order processing, accurate order fulfillment, and timely delivery. This translates into improved customer satisfaction and loyalty. Meeting customer demands promptly and efficiently can also provide a competitive advantage.

Improved Agility and Responsiveness

With supply chain optimization in place, businesses gain the agility to quickly respond to market changes, customer demands, and unexpected disruptions. Improved visibility and control over the supply chain enable informed decision-making and swift adaptation to fluctuating market conditions.

Risk Mitigation

Companies can proactively identify potential risks and devise effective strategies for risk mitigation. These strategies encompass diverse supplier portfolios, contingency plans, and bolstered supply chain resilience in the event of unexpected circumstances such as natural disasters or disruptions in the supply chain.

Collaboration and Efficiency Gains

Supply chain optimization often involves closer collaboration with suppliers, distributors, and other stakeholders.

Strategies for Effective Supply Chain Optimization

The goal of effective supply chain optimization is to maximize operational efficiency. Learn the different strategies to achieve this.

Collaborative Planning and Communication

This involves fostering strong partnerships and effective communication channels with suppliers, distributors, and other key stakeholders. By sharing information, insights, and forecasts, companies can align their plans and goals, optimize inventory levels, and enhance overall supply chain coordination. This strategy promotes proactive decision-making, minimizes information gaps, and reduces delays and inefficiencies.

Lean Principles and Waste Reduction

Applying lean principles is crucial for effective supply chain optimization. This strategy emphasizes the identification and elimination of waste throughout the supply chain, including excess inventory, overproduction, unnecessary transportation, and non-value-added activities. By adopting lean practices such as just-in-time manufacturing, pull-based systems, and process standardization, companies can achieve streamlined operations, reduced costs, and improved responsiveness.

Continuous Improvement and Innovation

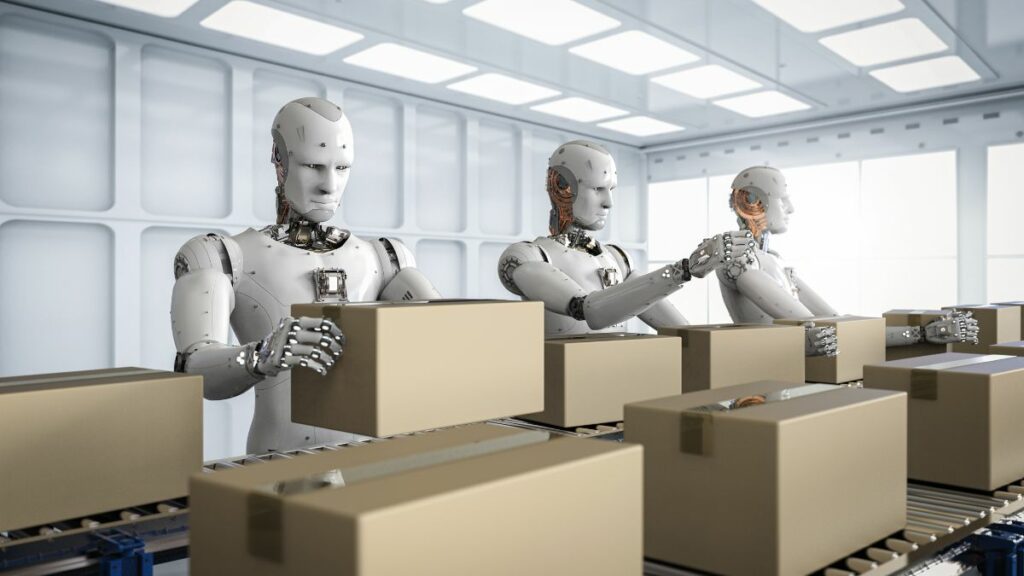

Supply chain optimization is an ongoing process that requires a commitment to continuous improvement and innovation. Companies should regularly evaluate their processes, identify areas for enhancement, and seek innovative solutions. This involves leveraging technology, embracing automation, and exploring emerging trends such as artificial intelligence and machine learning.

Integration of Supply Chain Technologies

Effective supply chain optimization relies on the integration of advanced technologies. This includes implementing supply chain management software, leveraging data analytics for demand forecasting and inventory optimization, utilizing real-time tracking systems for improved visibility, and adopting cloud-based platforms for seamless collaboration. Integrating these technologies enables companies to gain valuable insights, enhance decision-making, automate processes, and achieve greater operational efficiency and accuracy.

Key Takeaways

In conclusion, supply chain optimization is a critical driver of success for businesses in various industries. Embracing continuous improvement, innovation, and leveraging technology further strengthens the optimization process.

Casia Cross Better Logistics is a leading logistics solutions provider dedicated to optimizing supply chains for businesses worldwide. Our innovative approaches and tailored strategies enable businesses to unlock the full potential of their supply chains. Partner with us to transform your supply chain into a competitive advantage in today’s ever-changing business landscape.